![]()

| RCFAQ.com |

The complete radio control model airplane FAQ. |

![]()

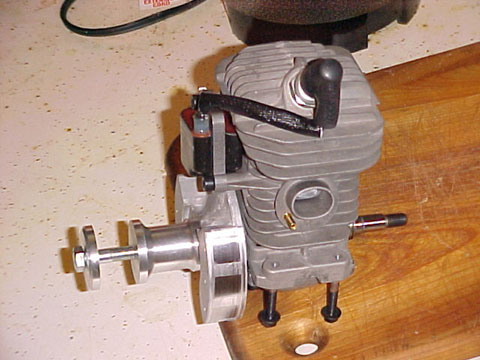

Converting a 46cc Poulan Model 2750 chainsaw for model airplane use. This 2.8ci engine is almost identical in power and weight to a BME 2.7 (44cc).

3. Carb Mounting for Poulans

![]()

Ralph Cunningham on the carb mount:

On mine I used some G10 epoxy board, 3/8 thick, routed out to the shape of the intake stub. The board just fits the oval, and I used Permatex Ultra Copper on the stub and under it. With the pulse fitting drilled and tapped for a flathead screw, and two 8/32 screws into the sides, there is no leak. The pulse now comes from a fitting tapped into the transfer port behind the carb. Two holes are drilled and tapped 180 degrees apart through the side of the epoxy board and the stub. 8/32 screws go all the way through the board and the stub, and are ground off smooth inside the stub. A small pressure tap is screwed into the cylinder through the transfer port to connect to another tap in the back plate of the carb. The carb is bolted onto the epoxy board so that the shaft is parallel to the cylinder and the throttle servo is connected directly to the end of the shaft. I use my CD ignition on the engine, so a new hub is made to replace the flywheel, saving the weight that and the coil. The ignition box is separate and weight about 4 ounces...R C ....

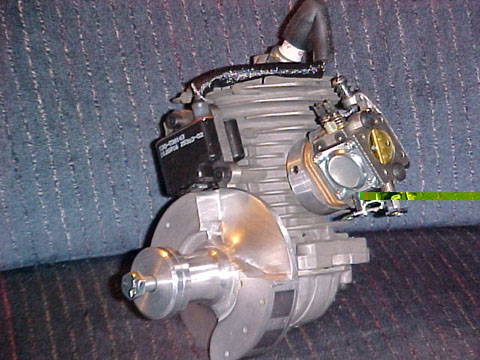

Flipflop described his method:

This shot shows the intake side of the engine. As you can see, the intake port is oval shaped and the brass tube for the crankcase pressure to the carb is very close to it. I made a pattern of the intake port including the brass tube and transfered it to a piece of aluminum the same thickness as the length of the intake port. The diameter of the aluminum is 1.650 giving me plenty of room for the two 5mm setscrews that hold the adapter to the port. Be careful here, the intake port is very thin cast aluminum and you need to make sure that you don't bear down too hard on the setscrews. The rest of it was pretty easy, I wanted the throttle arm closer the the crank centerline, so I just positioned the carb where I wanted it and used the metal carb spacer(gasket) to mark the location of the holes to mount the carb. (Whew) Next, I made a plywood spacer with the holes for the crank pressure and carb bolts. You have to make a 180*groove in this for the pressure to get to the carb. Don't forget to give this a coat of 30 minute epoxy. Lot of work, but it can be done.:

![]()

All of the information on

this web site is copyright 2000 by rcfaq.com. All rights reserved.

Revised: February 09, 2002 .

email webmaster@rcfaq.com