| RCFAQ.com |

The complete radio control model airplane FAQ. |

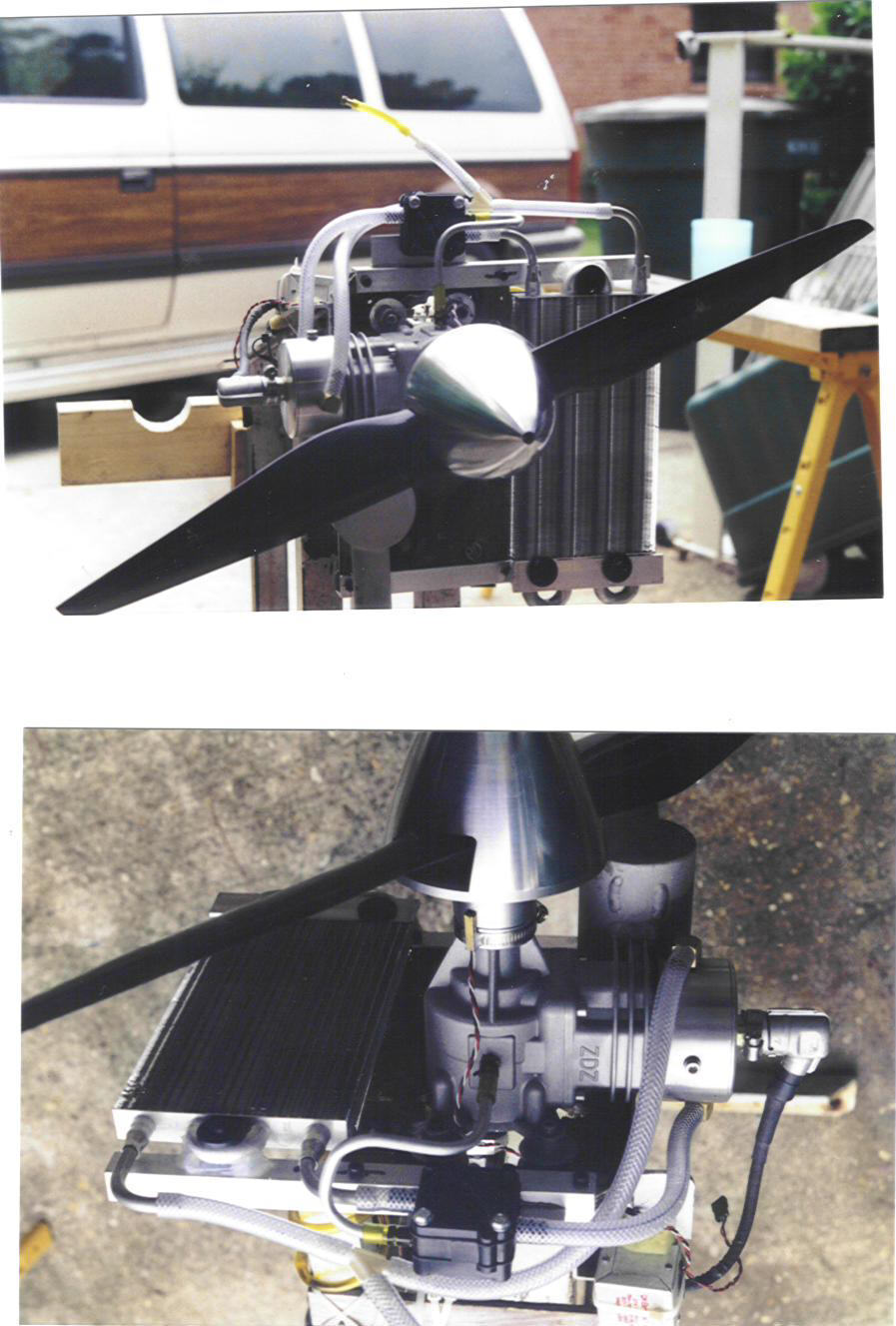

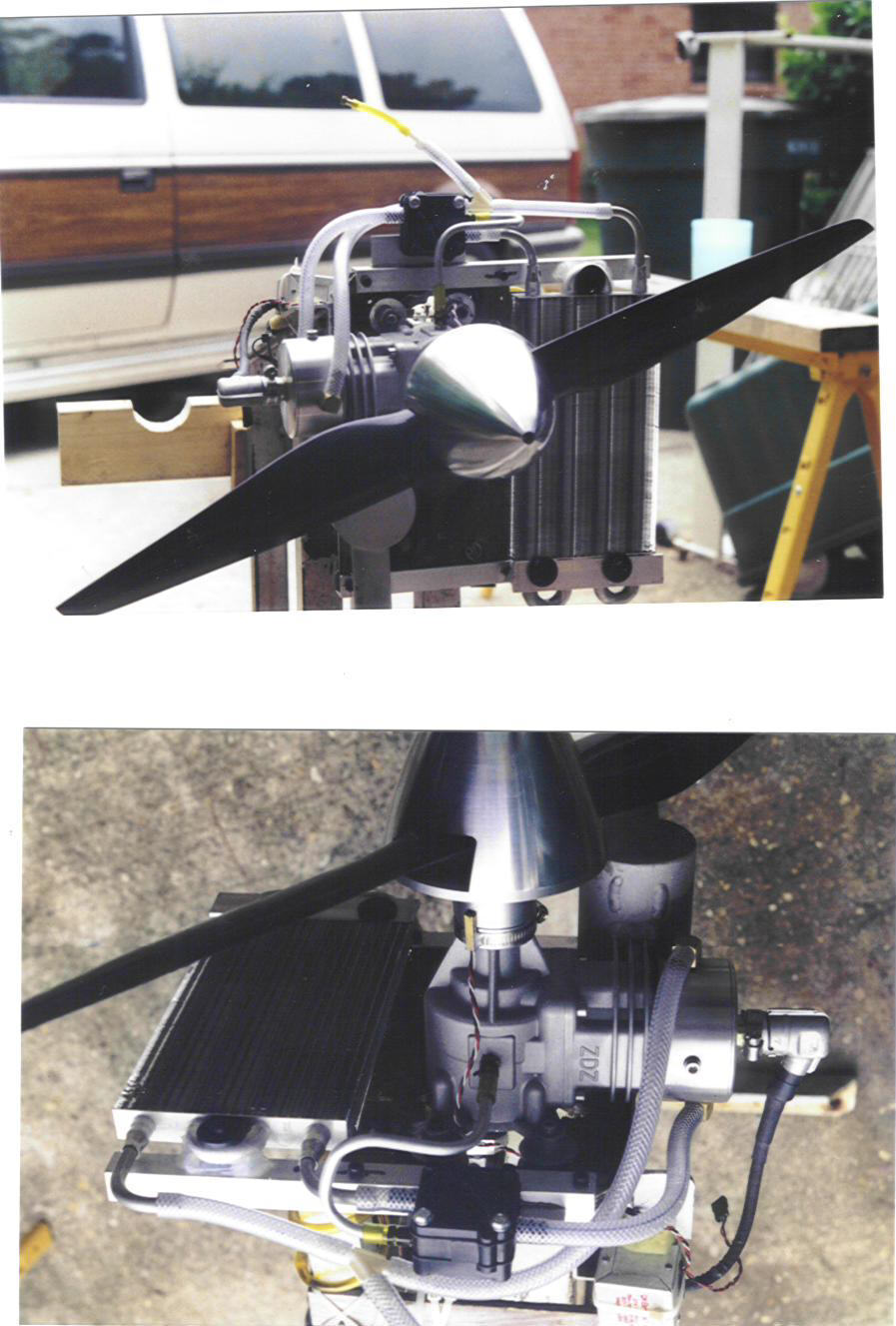

Below is a picture of a water cooled ZDZ 80cc engine. The conversion, information, and pictures were provided by Randy Villines.

Jump to:

Interesting that the subject of

tuning comes at this time as I was preparing to mention some of my own findings

on the subject. All of our cylinders are castings, as such, heat does some

negative things to them. As the cylinders expand, the bore (round at room

temperature) does not expand ROUND!!! At one temperature it may be

"egg" shaped in one direction and at 50 deg higher, it may be egg

shaped in another direction, or it may go on to be "oval" at yet

another temperature. No matter how well "broken-in," the piston

ring/s, can't keep up the seal and the power sags.

Now having said that, I have

successfully converted a ZDZ 80 to a "water-cooled" version. Air

cooled, it turned a Fuchs 26-10 steady at 5,800 rpm. As a water-cooled engine,

it turned the same prop at 6,200 rpm (steady). The temperature stability allowed

me to run the engine with a "tuned pipe" and realize a steady 6,700

rpm.

I am preparing a ZDZ 160 twin with the same type water-cooled heads, and then install the unit in some 40-44% plane. A custom radiator will be mounted in front of the engine.

The whole conversion is quite light, radiator, water, pump/s and I intend to

offer conversions on a custom basis. More info to come later, however if anyone

is even remotely interested, contact me and I can send photos.

It all started with a quest to get a "perfect" throttle response and smooth transition through that "dreaded" mid-range with a "no compromise" approach. I began experimenting a couple of years ago with tuned pipes, "tuned mufflers" and the such. I was successful in completely filling a 55 gallon drum with "scrap" mufflers and pipes that I had made myself.

Finally, I hit the

right combination and came up with a tuned muffler that would boost the power

AND was only 101 dB with a MEJZLIK prop and 99 dB with a Fuchs prop.

Quiet at it was the throttle response still sucked! Mid-range

still "burbled." More investigation was needed. To shorten this story

I'll tell you that one major culprit was the "heat and cooling cycle,"

(notice how differently your engine runs when it's cool and first started as

opposed to how it runs later after it warms up)?

I looked to "Ultra-lights" and how full scale

aircraft solve the problem. Full scale air-cooled aircraft have one of the same

problems that we have. (Now when I say "we have," I mean

"large" gasoline engines and "large" model aircraft.) Worse

case: On a hot summer day, we are a bit too lean to begin with. We do long

vertical up-lines, the engine gets "hot," then we chop power, and do

long vertical downlines, the engine gets "cold." At the bottom we

throttle up and the engine burbles............ hmmmmmm ................... whats

going on?

Well, we know at least part of what's going on. I discovered

that many homebuilt aircraft are using liquid cooled engines. The Rotax 912 and

914 are certified aircraft engines and have liquid cooled heads.

First, I found a company they makes custom aluminum

radiators, NASA, NASCAR, and home built aircraft are just a fraction of their

business. They can make a full functioning radiator the size of a cigarette

pack! Yes, it is expensive, (about the same as one for your car) but not too

outrageous.

Next, I took my ZDZ 80 apart, machined off all the cylinder

fins down to the exhaust port, and machined a water jacket and installed two

fittings as well as a "air purge" valve.

Specs:

When I machined the fins off the cylinder, the cylinder lost 4 oz.

The water jacket added 3 1/2 oz back on. Pump weighs 2.5 oz. , radiator is 5-7

oz., and the system carries 12 oz of water.

Florida air temp on first test day

was 95, humidity was (miserable) 85%. After two hours of break-in the engine was

"tweaked out" and the afore mentioned rpm was recorded.

During the initial tests, the coolant

temp was only 120 deg. Later when I installed a tuned pipe and ran the rpm way

up, the coolant temp went only to 135 deg. This tells me that a much smaller

radiator than I am using now (7 oz) can be used. The target temperature is 160

deg. coolant temp, and it turned out that the size radiator quoted should gave

an operating temp of approx. 140 deg.

The radiator manufacturer is Griffin Radiator, and the price is approx. $200 ea. Very helpful people there. After consulting with there engineer, it was decided that a 80cc engine needed a radiator 3.5"x 5.5"x 1.25". (larger than a cigarette pack). The pump I am using has no moving parts. It is a "new" diaphragm pump that is now on the market. It is made of polycarbonate plastic and has neoprene "innards" and will take 180 deg. The pump works off crankcase pulses (it will fill a 55 gal. drum, mounted 10' high!!!). I sell the pump by the way $25 ea.

I can convert most large engines such as the DA, or 3W or ZDZ. The main

requirement is that the cylinder has a "center" located spark plug.

Most "offset" plug locations such as on chainsaw cylinders cannot be

easily machined.

A powerful engine like the ZDZ 80, uses a lot of fuel, which translates to heat.

I have tried restricting the water flow and the old fashion Model "T"

thermal siphon idea is not sufficient to carry away the heat.

All of the information on this

web site is copyright 2000 by rcfaq.com. All rights reserved.

Revised: April 18, 2006

.

email webmaster@rcfaq.com